Processing : Yeast Anaerobic Washed

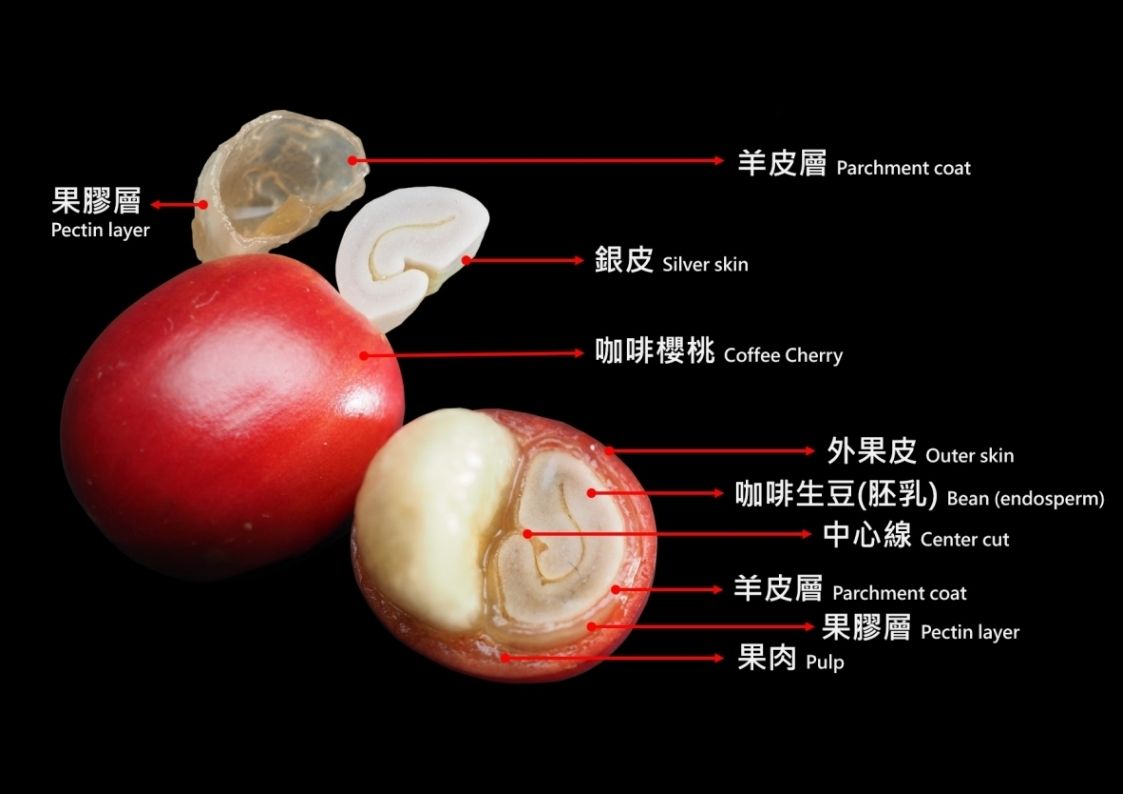

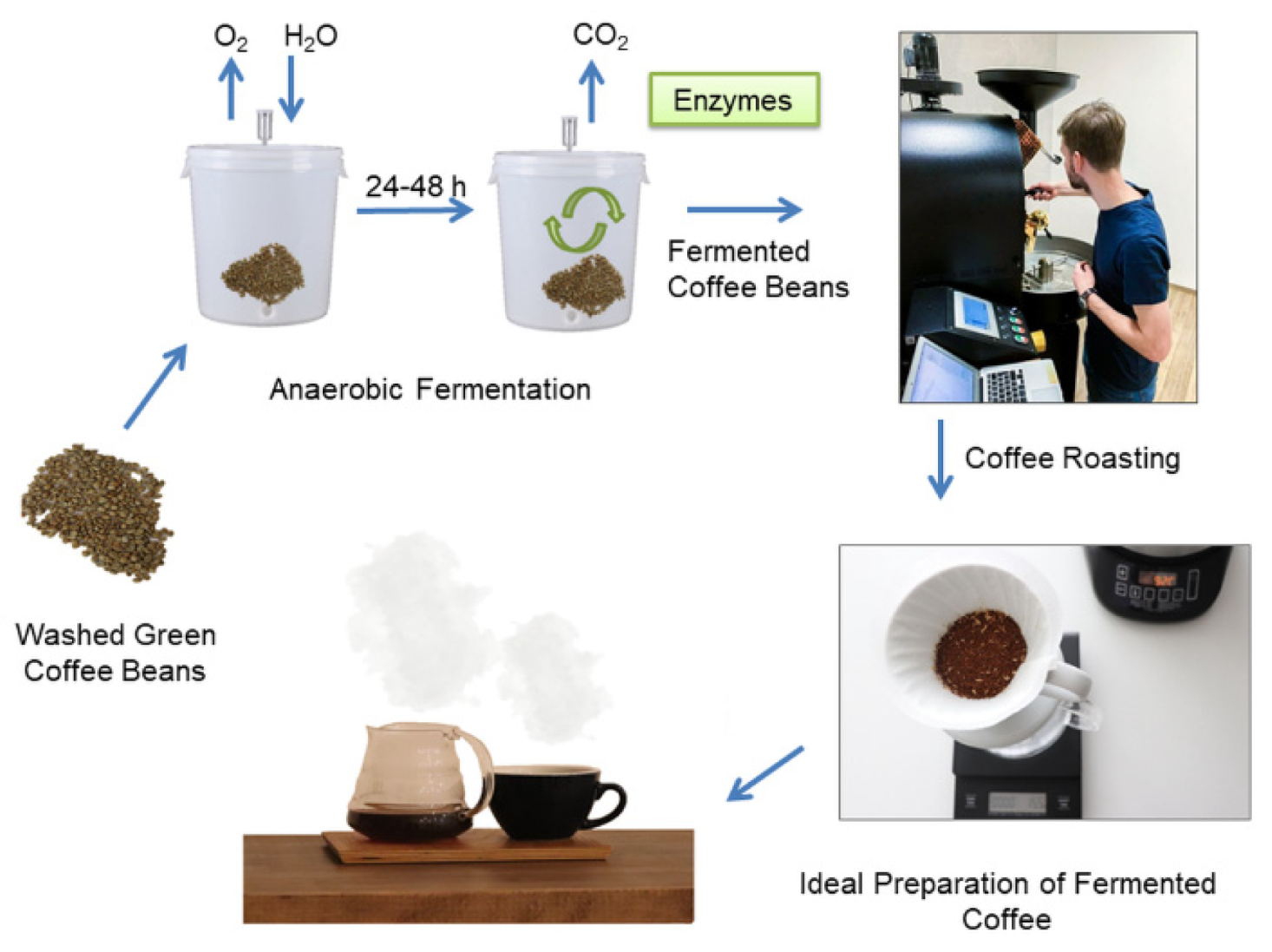

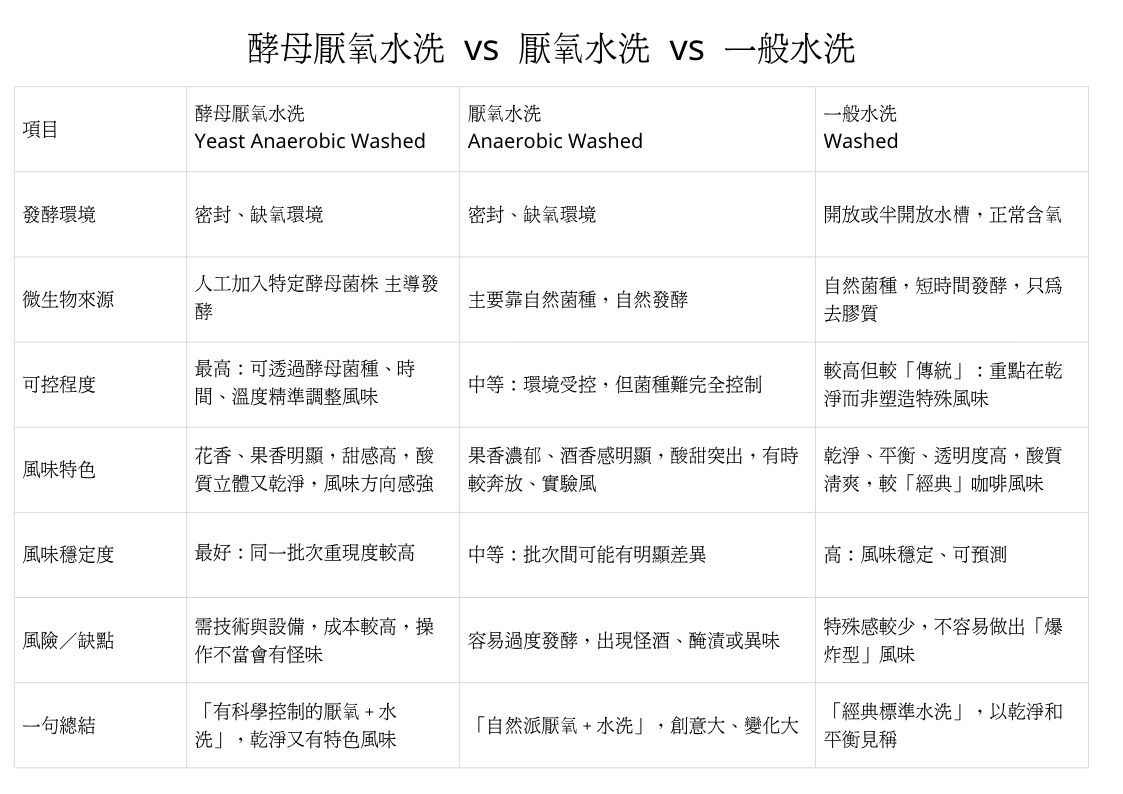

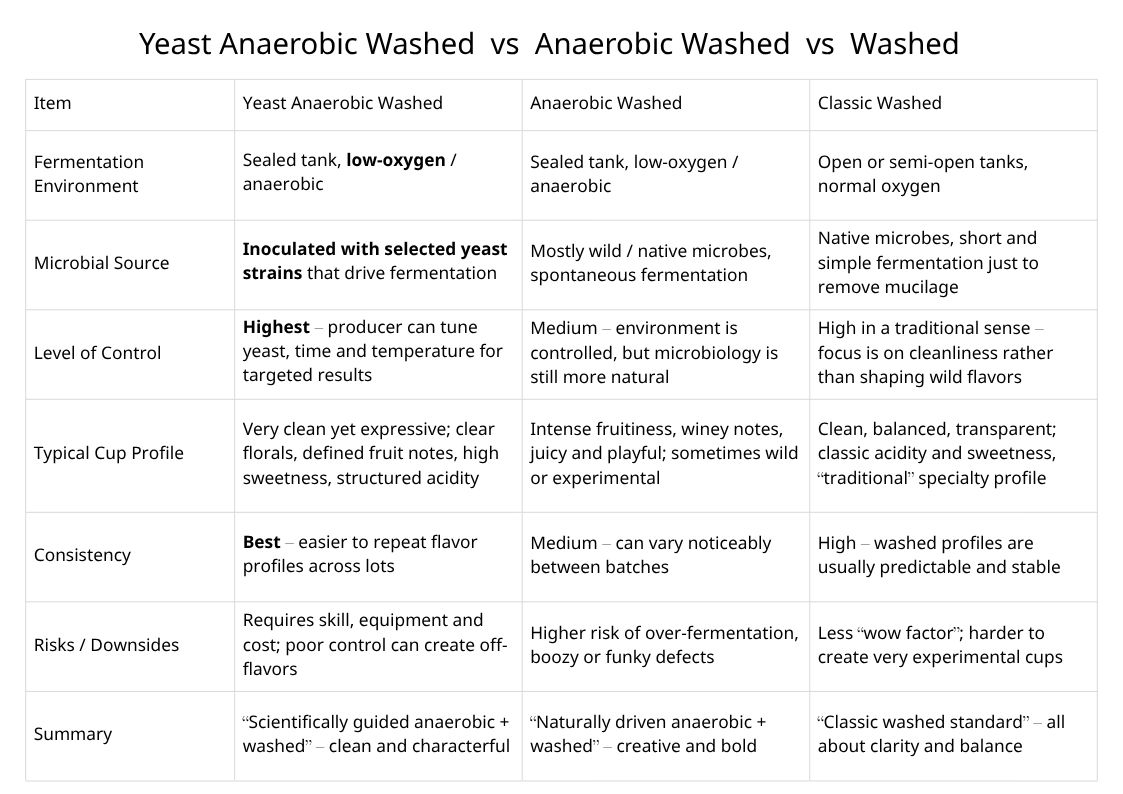

The Yeast Anaerobic Washed process is an innovative method that combines the precision of modern microbiology with the cleanliness of traditional washed coffee. After harvesting, ripe coffee cherries are carefully sorted and depulped to remove the skin and pulp, leaving the mucilage-covered parchment beans. These beans are then placed in sealed stainless-steel or plastic tanks where oxygen levels are kept extremely low. At this point, producers inoculate the tanks with selected strains of yeast—most commonly Saccharomyces cerevisiae—to control fermentation in a strictly anaerobic environment.

During fermentation, which typically lasts between 24 and 72 hours depending on temperature, yeast metabolism converts sugars and mucilage into a range of aromatic compounds such as esters and alcohols. These compounds give the coffee its distinctive floral and fruity notes while enhancing sweetness and roundness in the cup. The absence of oxygen directs microbial activity toward lactic and alcoholic fermentation pathways, producing lactic acid and volatile compounds that contribute to a bright yet smooth cup profile.

The defining feature of the Yeast Anaerobic Washed process is its high degree of control. By introducing a specific yeast culture, producers can standardize fermentation, minimize inconsistencies, and achieve stable cup quality across harvests. The resulting coffees are exceptionally clean and expressive, often showing refined florals, citrus brightness, and stone-fruit sweetness—making this process especially well suited for aromatic varieties such as Pink Bourbon.